.png)

.png)

Transformer is a highly capital intensive equipment and is the costliest item in the substation. With the advent of many technical inventions and research, the design and manufacturing practices in transformers are undergoing changes. Demand for more and more cost effectiveness and equally so for more quality, reliability is increasing.

The Organization has profoundly invested in building a team, comprising of Expert Engineers, Supervisor, and Technician to counter all services related to transformer erection and commissioning, overhauling and fault finding at site.

Repairing & Servicing Range:

Transformer Erection and Commissioning at Site:

We have an Licensed Electrical contractor and an Dedicated and Experience team to perform services of Transformer at site, we also take AMC for Power and Distribution Transformer. Our team is well trained and equipped to perform all the erection and commissioning work up to 50 Mva 132 kV class.

Scope of Work for Performing Services at site:

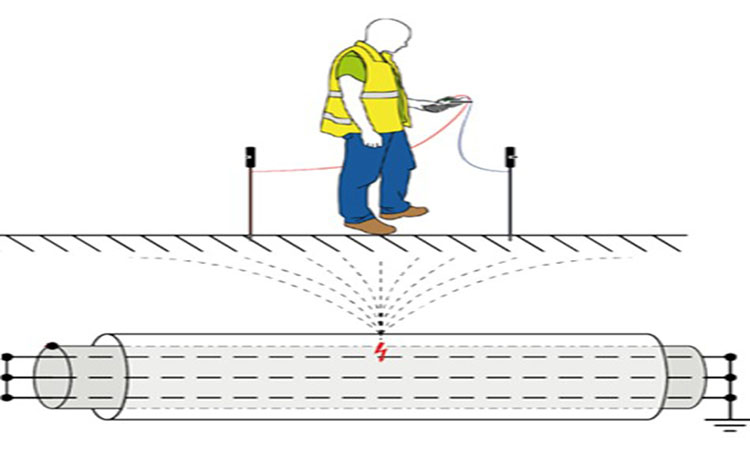

In Underground electricity distribution system, the cables used are placed in the ground or in some form of ducts, whenever there is a fault in these cables, it becomes difficult to locate and repair the fault as conductors are not visible, There are many method to locate the faults along with the new detection technology and electrical items, which makes the task easier and less time consuming. There are different type of method for different faults which make it safer and efficient to locate the faults without damaging the cable.

We have an experienced and Expertise team for finding out cable fault for LT and HT Cables up to 33 KV . Our Team is equipped with latest machinery and equipment to find any leakage or Cable Puncture.

We use thumping method for shorter cables, a Thumper is set to thump repeatedly and then walking along the cable route to hear the thumping sound. The higher the DC voltage applied, the louder will be the resulting thump.

For Relatively longer length of cable we use High Voltage Radar method to find the cable fault, Surge Generator cable fault locators ("Thumpers") provide pre-location and pinpoint cable fault location. Cable fault pre location using ICE (Impulse Current Method) is preferred for extensive underground cable fault location and pinpointing cable faults in water damaged cable joints. Precise location of cable faults through surge generator fault locators (cable thumping) is very quick and limits expensive excavation by pinpoint accuracy.