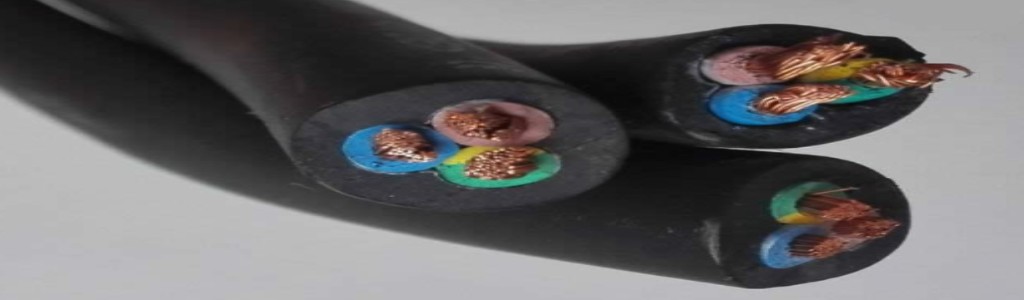

EPR Rubber cables

Ethylene Propylene Rubber is a generic term for a wide range of polymers based on copolymers of ethylene and propylene.

EPR is widely used as an insulation material for electric cables due to its high dielectric strength but it is also used as a sheathing material exhibiting excellent ozone and weathering resistance. EPR has a wide thermal range typically in the region of -55°C to 150°C. Supreme grade materials like annealed tinned copper (Class 5) and heat resisting elastomer is used in the manufacturing process to ensure high-grade end products.

Manufacturing Range: Our Range starts from Single core 1.5 Sqmm to 300 Sqmm and Multi Core 2,3,4 core 2.5 Sqmm to 300 Sqmm. This Cables can be Mfg. in Combination of EPR/CSP and EPR/PCP as per the customer Requirement.

Standards: Cables are Mfg. as Per IS 9968(Pt-1)/1988.

Salient Features:

EPR rubber is noticeably softer than Natural rubbers so can be used as a replacement material in many applications. Where greater hardness is required, the EPR compound can be blended with polyethylene (PE) or polypropylene (PP) to achieve improved physical properties. Mechanical properties include resistance to compression, cutting, impact, tearing and abrasion.

Although EPR does not offer a good resistance to oils, it is resistant to a wide range of other chemicals including many acids, alkalis and organic solvents. It is also highly resistant to moisture.

Like XLPE insulation, EPR Insulation is suitable for many higher voltage applications and while its dielectric properties are not as good as those of XLPE it does have some important advantages over XLPE including extra flexibility, reduced thermal expansion, and low sensitivity to water treeing.

Applications:

- Power Cables.

- Mining cables.

- Motor Wire.

- Device Cables.

.png)